When it comes to product development, timing can make or break a launch. This is especially true for entirely new products or startup endeavors, where quality and efficiency are critical to a competitive edge. To ensure a seamless product launch, involve a contract manufacturing partner in the early stages of product development rather than at the later phases of production planning. By doing so, you'll benefit from the manufacturing partner’s expertise and experience, enabling you to transition smoothly from a product concept to scalable production.

The Goal of a Successful Product Launch

Product development is a complex and detailed process that begins with conceptualization and ends with delivering a finished product to market. The end objective isn’t simply designing a good product. The objective is to successfully launch a product that can serve its intended purpose. To get there, you must carefully plot out the contours of your vision and refine things like manufacturing feasibility and engineering requirements, starting early in the design phase.

You then look at things like product performance expectations, quality and inspection guidelines, and manufacturing strategy, among other notable elements, until you finally reach the production phase, where your creation becomes a reality. Each step, from the initial sketches to the final assembly line, must be meticulously planned and executed to ensure the finished product meets the necessary requirements.

Collaborative Product Development Strategy

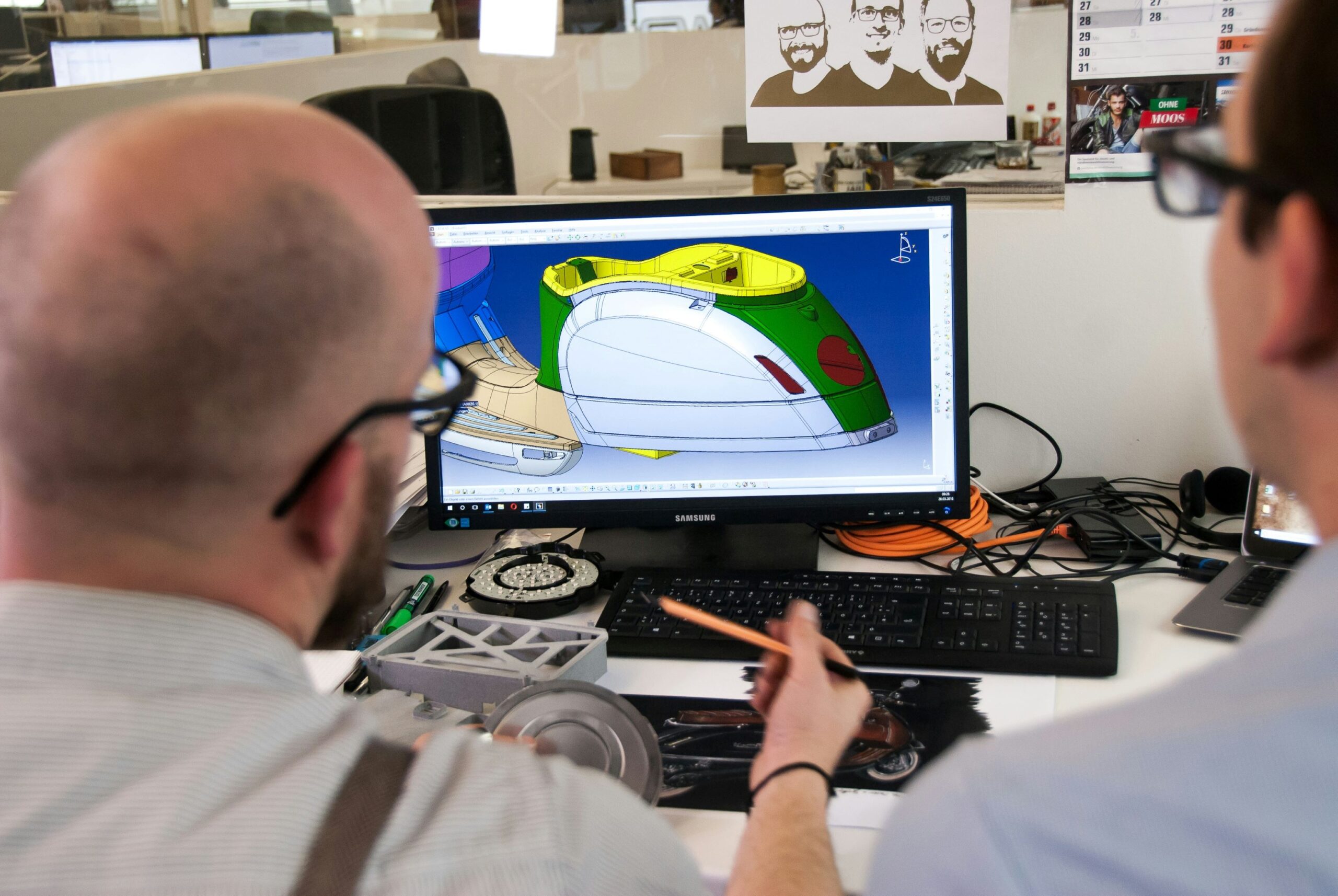

The success of a product launch depends on the collaboration between product designers and manufacturing experts. Product designers bring forth innovative ideas, while contract manufacturers possess the technical know-how necessary to bring these concepts to life.

As your design takes shape, your product's manufacturing strategy should evolve concurrently. Rather than merely providing specifications to be followed, a contract manufacturer can collaborate with the product designer to identify potential challenges and opportunities, improve the design for manufacturability, and establish a production plan that maximizes efficiency while minimizing costs.

Therefore, engaging a contract manufacturing partner at the start of the development process is valuable to ensure your product launch is on time, on budget, and meets high-quality standards.

Consider the design phase as a brainstorming session where creativity meets practicality. This is an opportune moment for the contract manufacturing partner to contribute their expertise, suggesting materials, processes, and optimizations that align with both the design vision and the realities of production.

Planning Ahead with Manufacturing Expertise

Collaborating with a contract manufacturer early on in your product development journey can significantly increase the chances of a successful product launch. Their involvement extends beyond the design phase and encompasses every aspect of the product development process, from quality planning to supply chain management. By partnering with a contract manufacturer, you can benefit from their expertise in these critical areas and ensure a streamlined path from prototype to production. This approach minimizes the risks of delays, defects, and cost overruns, ultimately leading to a successful product launch.

Product Development Quality Plans

Quality planning is a significant aspect of product development. Planning well ensures that every component meets the stringent standards set for the finished product. This step involves not just inspecting the final product but integrating quality control measures at every stage of the manufacturing process.

By involving a contract manufacturer during the initial stages of the design process, product owners can identify potential quality issues early on and implement proactive measures to address them. From determining Production Part Approval Process (PPAP) requirements to developing supplier control plans, contract manufacturing partners can help ensure that the final product meets the highest standards of quality and reliability.

Developing Supply Chain Strategies

Similarly, supply chain planning is another area where early engagement with a contract manufacturer can make an impactful difference. By collaborating closely with a contract manufacturer, product owners can map out the entire supply chain, from sourcing raw materials to final assembly.

This comprehensive, upfront approach helps identify potential bottlenecks and vulnerabilities, allowing for the development of contingency plans to mitigate risk. With this level of foresight enabled by a manufacturing partner and their supply chain planning efforts, your journey to product launch can stay on track, even when faced with unforeseen challenges or disruptions.

Moving from Concept to Production

Actualizing meticulously crafted production plans is where contract manufacturing partners shine. They are not just building your product but orchestrating relationships and managing communications with suppliers, manufacturers, and logistics providers to bring your idea to reality seamlessly.

Early collaboration enables contract manufacturers to develop tailored procurement, assembly, and inventory management strategies, laying the foundation for a reliable and scalable production process. Moreover, early involvement allows contract manufacturers to develop efficient manufacturing processes, leveraging their expertise in lean principles, flexible manufacturing, and quality assurance to streamline operations and enhance productivity.

Ultimately, by partnering with contract manufacturers early on, product owners can mitigate risks, reduce costs, and accelerate time-to-market, setting the stage for a successful product launch and long-term success in the market.

Continuous Improvement and Manufacturing Execution

Launching production hand-in-hand with the product owner is not a mere gesture; it's a strategic move. This synchronized approach ensures that any challenges or hiccups can be addressed in real time, minimizing disruptions and keeping the project on track.

Contract manufacturing partners help streamline production processes from the outset and establish a culture of continuous improvement that can drive ongoing enhancements throughout the product lifecycle.

Ultimately, by engaging contract manufacturing partners at the start of the design phase, product owners can capitalize on their expertise to create more efficient and cost-effective manufacturing processes, leading to improved quality, reduced lead times, and greater competitiveness in the market.

As production scales, contract manufacturing partners also enable you to grow with capital efficiency and tailor growth plans with each intricacy of your product in mind. Rather than use production plans that made sense for initial assembly programs, higher demand or changing market regulations may require you to increase efficiency or plan for automation. A contract manufacturing partner that's been with you for the long haul likely already has tailored strategies in mind and has the background of your product to execute scalable plans effectively.

Strategize Your Product Development Process

Collaborating with a contract manufacturing partner at the beginning of your product development process can unlock a wealth of knowledge and expertise that can mitigate risks while expediting product launches. By working together from the get-go, you can optimize the journey from concept to production, ensuring that the final product is of the highest quality, efficiency, and reliability.

Want to start on your product development journey? Get in touch with the team at Edison Manufacturing and Engineering today!